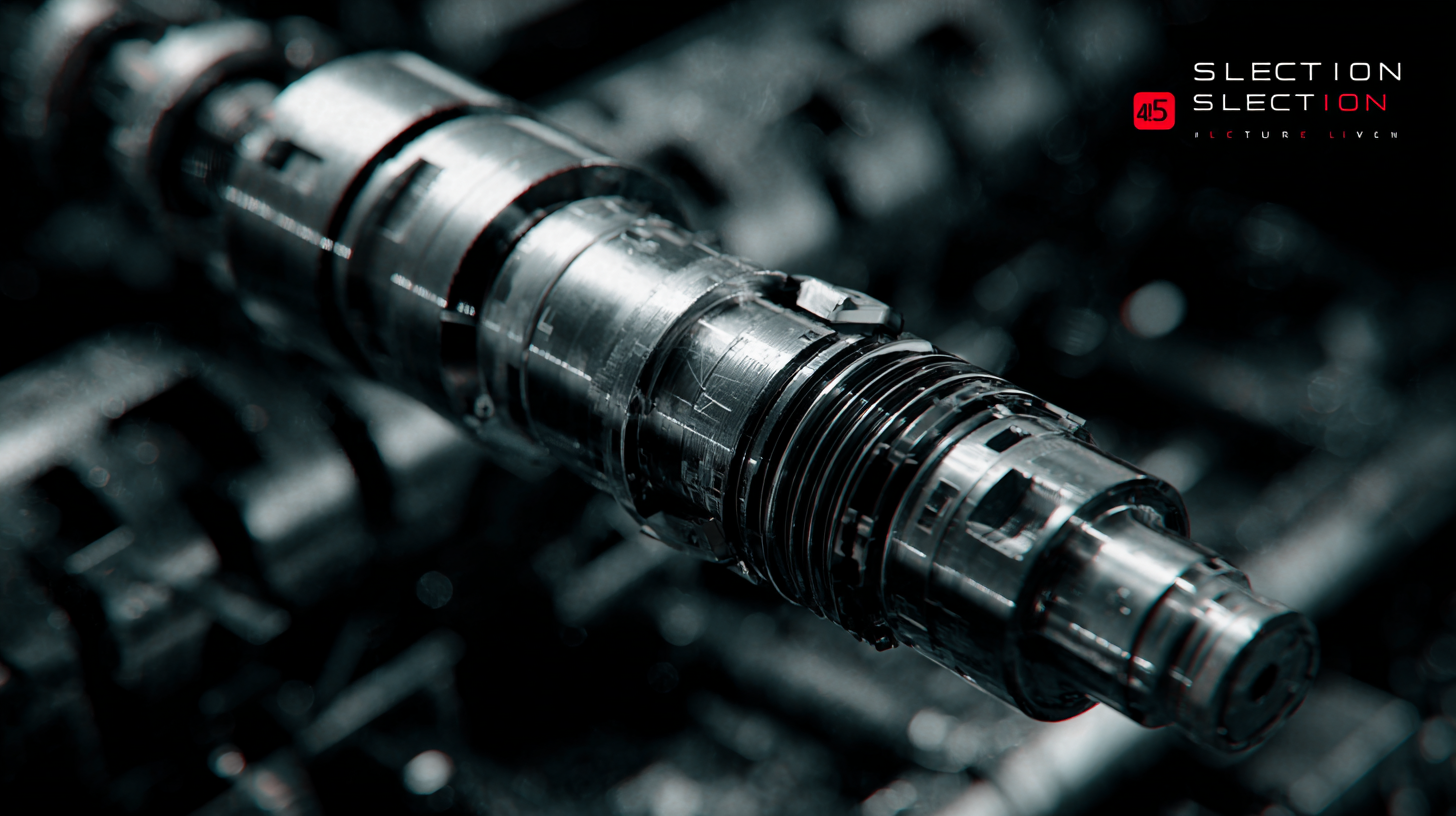

Ultimate Guide to Selecting the Best Injection Moulding Screw Barrel for Your Manufacturing Needs

In the realm of manufacturing, particularly within the plastics industry, the selection of the right injection moulding screw barrel is crucial for optimizing production efficiency and product quality. According to recent industry reports, the global injection molding market is projected to reach over $500 billion by 2025, highlighting the significant demand for effective and reliable machinery components. A well-chosen injection moulding screw barrel not only enhances the consistency of the molding process but also plays a pivotal role in minimizing operational issues such as material degradation and inconsistent output. As manufacturers seek to improve their production capabilities amidst competitive pressures, understanding the intricacies involved in selecting the appropriate screw barrel becomes more vital than ever. This guide aims to address common problems associated with various types of injection moulding screw barrels, providing insights to help manufacturers make informed decisions that align with their unique operational needs.

Key Factors to Consider When Choosing Injection Moulding Screw Barrels

When selecting an injection moulding screw barrel, several key factors must be considered to ensure optimal performance and efficiency. The compatibility of the screw design with the material being processed is crucial. According to a report by the Plastics Industry Association, nearly 30% of production issues stem from mismatched screws and barrels, leading to increased cycle times and defective products. Understanding the material's viscosity and thermal properties can help manufacturers choose a screw design that minimizes shear and maintains consistent quality.

Another vital aspect is the barrel length-to-diameter (L/D) ratio, which influences both the melting process and the mixing quality of the polymer. Research published by the Society of Plastics Engineers indicates that a higher L/D ratio can enhance material processing by providing better melting efficiency and improved melt homogeneity. Industries typically utilize an L/D ratio range from 20:1 to 30:1 for standard applications, but customized solutions may require ratios exceeding 30:1 to meet specific production demands.

Durability and wear resistance of the screw barrel are also paramount. The use of advanced materials and coatings can significantly extend the life of the barrel. Data from the Injection Molding Machinery Manufacturers Association shows that investing in high-quality materials can reduce maintenance costs by up to 25%, which is vital for manufacturers looking to optimize their operational budgets while maintaining production quality.

Top 5 Types of Injection Moulding Screw Barrels for Optimal Performance

When selecting the best injection moulding screw barrel for your manufacturing needs, understanding the different types available is crucial for optimal performance. The die head, for instance, plays a vital role in shaping the material as it exits the barrel. It ensures a consistent flow and dimensional accuracy of the injected parts, which is essential for maintaining quality in production.

Another important component is the standard extruder head, which provides the necessary pressure and heat to melt the thermoplastic material before it enters the mould. Its design directly impacts the homogenization of the material, affecting both the quality and efficiency of the injection process. Additionally, the extruder barrel is fundamental, as it houses the screw and acts as the conduit for the melted material, allowing for optimal mixing and temperature control.

Incorporating machine learning models in the optimization of injection moulding processes can further enhance performance. These technologies analyze data to predict outcomes, enabling manufacturers to fine-tune parameters for improved efficiency and quality control. By exploring these aspects, manufacturers can make informed decisions when it comes to selecting the right screw barrel, ensuring that their production processes are both efficient and effective.

Ultimate Guide to Selecting the Best Injection Moulding Screw Barrel for Your Manufacturing Needs

| Screw Barrel Type | Material Compatibility | Processing Temperature Range (°C) | Output Rate (kg/h) | Best For |

|---|---|---|---|---|

| Standard Screw | General-purpose thermoplastics | 180 - 220 | 30 - 80 | Common manufacturing applications |

| Barrier Screw | High-viscosity polymers | 200 - 250 | 40 - 100 | Complex parts with diverse materials |

| Mixed Screw | Various thermoplastics and rubber | 180 - 240 | 20 - 90 | Hybrid applications |

| Compression Screw | High-density materials | 250 - 300 | 50 - 120 | Heavy-walled parts |

| Screw with L/D Ratio | All thermoplastics | 180 - 230 | 30 - 70 | Precision applications |

7 Essential Materials for Long-Lasting Screw Barrels in Manufacturing

When it comes to selecting the best injection moulding screw barrels for your manufacturing needs, the materials used in their construction play a crucial role in durability and performance. Among the many options available, a few essential materials stand out for their long-lasting qualities. One such material is high-speed steel (HSS), known for its exceptional hardness and resistance to wear. This makes HSS an excellent choice for screws and barrels that need to withstand high levels of stress and temperature during manufacturing processes.

Another important material is stainless steel. Its corrosion resistance, coupled with high strength, ensures that screw barrels remain effective in diverse environments, especially when working with corrosive plastics. Additionally, there are also specialized alloys that can enhance specific attributes such as thermal conductivity and tensile strength. Materials like chrome-molybdenum steel are especially beneficial for applications requiring high fatigue resistance. By choosing the right combination of these materials, manufacturers can ensure that their injection moulding screw barrels not only meet performance requirements but also have a longer service life, reducing downtime and maintenance costs.

Common Mistakes to Avoid in Selecting Injection Moulding Screw Barrels

When selecting an injection moulding screw barrel, many manufacturers often make common mistakes that can lead to costly ramifications. One prevalent error is overlooking the importance of material compatibility. Different materials require specific barrel designs and materials to perform optimally. Ignoring this factor can result in poor processing, leading to defects in the final product and reduced production efficiency. It's essential to thoroughly understand the material properties and match them with the barrel specifications effectively.

Another mistake is failing to consider the right screw design for the application. Each screw type is engineered for specific tasks, such as mixing, melting, or conveying. Choosing a one-size-fits-all approach can compromise the quality and consistency of the output. Furthermore, neglecting maintenance and operational parameters can lead to premature wear and tear of the screw barrel, increasing downtime and replacement costs. Proper analysis and understanding of both your application and the equipment can significantly enhance performance and longevity, ensuring that your manufacturing needs are met efficiently.

4 Ways to Assess the Quality and Efficiency of Screw Barrels Before Purchase

When selecting the best injection moulding screw barrel, it is crucial to assess their quality and efficiency to meet your manufacturing needs. A comprehensive evaluation can be achieved through multiple approaches. For instance, inspecting the material composition and finish is vital, as high-quality barrels are typically made from durable materials that resist wear-and-tear, thus ensuring longer service life and consistent performance.

Additionally, examining the performance parameters—such as the melt flow rate and temperature resistance—can provide insights into how well the screw barrel will operate under specific production conditions. Reports indicate that industries are increasingly adopting advanced screw barrel designs that enhance efficiency; for example, improvements in screw geometry can lead to enhanced mixing and reduced cycle times, directly impacting a manufacturer's output and profitability.

Moreover, as evidenced by the recent growth of Zhejiang Huaye in the plastic machinery sector, achieving a revenue growth while maintaining high quality in screw barrel production underscores the importance of strategic investments in technology. With the global market for innovative manufacturing solutions projected to continue growing, ensuring that your chosen screw barrel meets these stringent performance benchmarks will be essential for maintaining competitive advantage.