How to Select the Best Extruder Screw Barrel for Optimal Production Efficiency

In the world of plastic manufacturing, the efficiency of production heavily relies on the quality and design of the extruder screw barrel. Selecting the right extruder screw barrel can significantly impact not only the overall production efficiency but also the maintenance costs and after-sales service benefits that come with it. As manufacturers strive to optimize their processes and output, understanding the various aspects of extruder screw barrels becomes essential. This blog aims to guide you through the intricate selection process, highlighting the importance of choosing an extruder screw barrel that aligns with your specific production needs while considering factors such as material compatibility, design differences, and long-term service support. By the end of this article, you will be equipped with the knowledge to make informed decisions that enhance your production efficiency and reduce operational costs.

Factors to Consider When Choosing an Extruder Screw Barrel

When choosing the best extruder screw barrel, it is essential to consider several critical factors that directly impact production efficiency and product quality. One of the most significant aspects is the barrel temperature. Operating within a specific temperature range, typically between 100-150°C, can greatly influence the physical and functional qualities of the extrudate. Maintaining optimal temperatures not only ensures the correct melting and processing of materials but also helps prevent degradation of sensitive ingredients.

Another key factor is the screw speed, which affects the residence time of materials within the extruder. Adjusting the screw speed between 110-350 RPM can enhance mixing and ensure a homogeneous product. Additionally, the moisture content of the feedstock, ideally maintained within a 12-20% range, plays a crucial role in the extrusion process. By fine-tuning these parameters, manufacturers can achieve better end-use characteristics in their extruded products, proving that careful selection and adjustment of these variables are vital for optimal production efficiency in extruder operations.

Understanding Different Types of Extruder Screw Barrels and Their Applications

When selecting an extruder screw barrel, it is crucial to understand the various types available and their specific applications to enhance production efficiency. Extruder screw barrels are primarily categorized into three types: single-screw, twin-screw, and conical twin-screw extruders. According to a recent industry report, the global twin-screw extruder market is projected to grow at a CAGR of 6.0% from 2021 to 2026, driven by their versatility and ability to handle a wide range of materials, including polymers, food products, and pharmaceuticals.

Single-screw extruders are often favored for their simplicity and cost-effectiveness, making them ideal for standard applications involving thermoplastics. In contrast, twin-screw extruders offer superior mixing capabilities and are essential for applications requiring precise control over material properties, such as compound mixing and reactive extrusion. A report by Mordor Intelligence highlights that twin-screw extruders account for nearly 40% of the market share in extrusion machinery due to their extensive use in the food processing and plastic industries. Understanding these differences can significantly impact production outcomes, enabling manufacturers to choose the appropriate equipment for their specific needs.

How to Select the Best Extruder Screw Barrel for Optimal Production Efficiency

| Type of Extruder Screw Barrel | Material Used | Applications | Production Efficiency |

|---|---|---|---|

| Single Screw Barrel | Carbon Steel | General Purpose Plastics | Moderate |

| Twin Screw Barrel | Alloy Steel | Compounding and Mixing | High |

| Barrier Screw Barrel | Stainless Steel | Recycling Applications | Very High |

| Corruated Screw Barrel | Carbon Steel with Chrome Coating | Specialty Polymers | High |

| Specialized Screw Barrel | Varied Alloys | Biomedical and Food Applications | Optimal |

Materials and Coatings: Enhancing Durability and Performance

When selecting the best extruder screw barrel, the choice of materials and coatings is critical for enhancing durability and performance. High-quality materials can significantly impact the longevity of extruder screws, with reports indicating that using alloys such as H13 or S7 can improve wear resistance by up to 40% compared to standard steel options. This increased durability leads to reduced downtime and maintenance costs, making it a vital consideration for manufacturers looking to optimize production efficiency.

Coatings also play a pivotal role in performance enhancement. For instance, applying ceramic or chrome coatings can reduce friction and limit the build-up of contaminants, ultimately leading to smoother operation and higher output rates. A recent industry study highlighted that extruders equipped with advanced coatings can achieve up to 15% more throughput under similar operating conditions, which is crucial in meeting the increasing demands for production efficiency and product quality in modern manufacturing settings. By carefully selecting both the materials and coatings for extruder screw barrels, manufacturers can ensure they maximize the operational effectiveness of their extrusion processes.

Extruder Screw Barrel Materials and Performance Comparison

This chart compares the performance of different materials used in extruder screw barrels. The efficiency is measured based on durability and performance ratings.

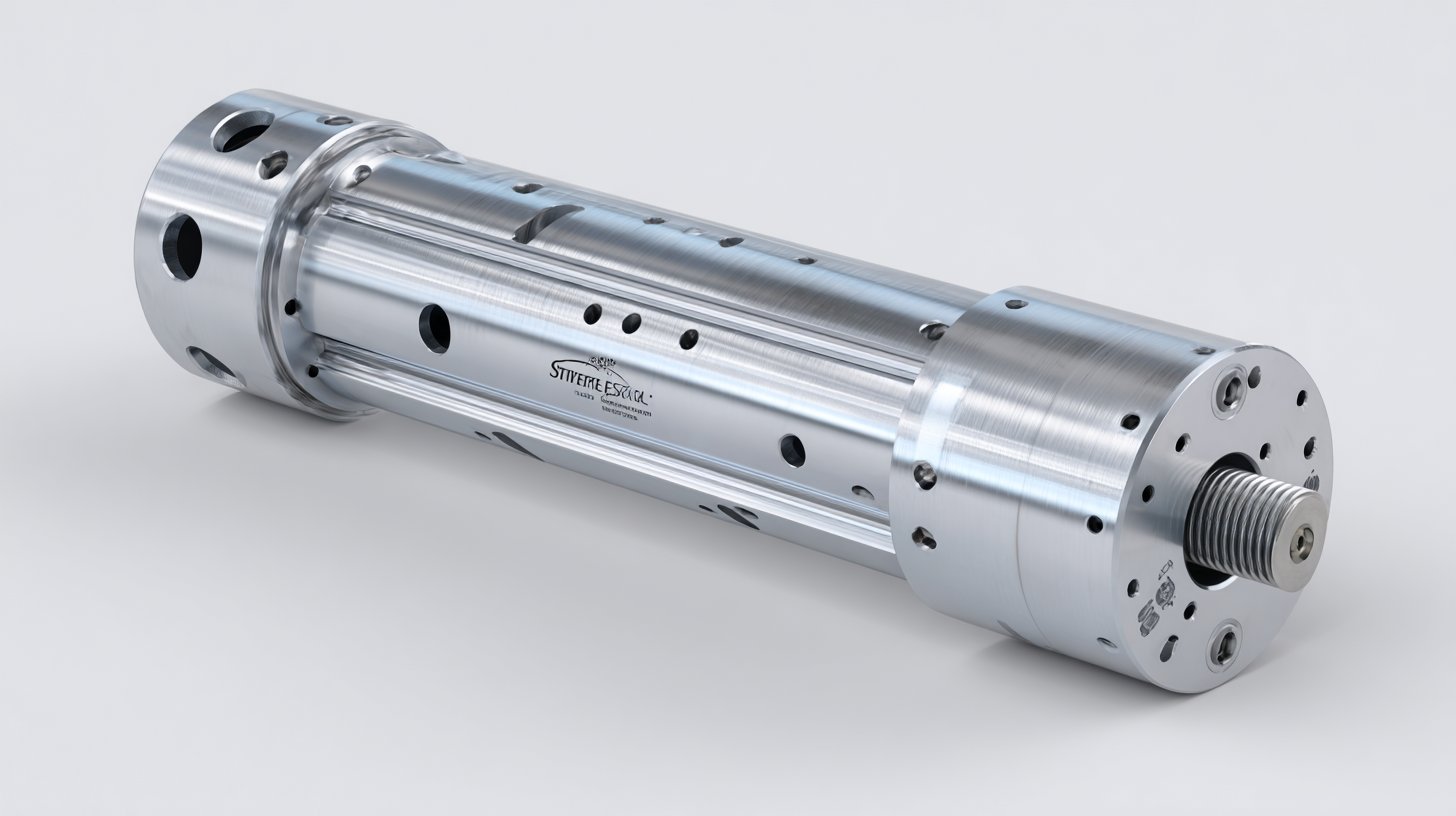

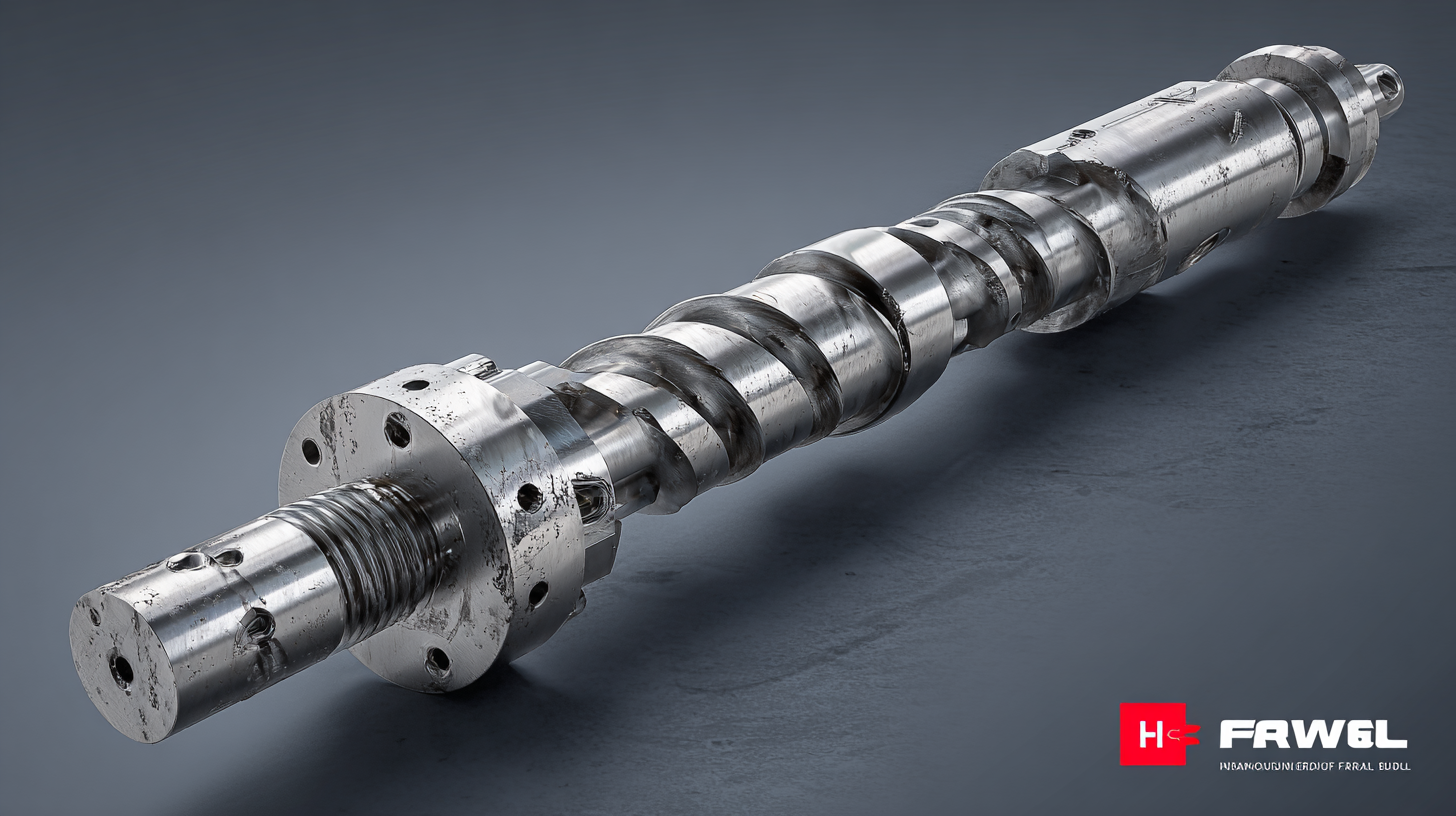

Impact of Screw Geometry on Production Efficiency and Output Quality

Screw geometry plays a vital role in determining the efficiency and quality of production in extrusion processes. From the design of the screw flights to the arrangement of mixing elements, each aspect of screw geometry can significantly impact material flow, melt quality, and ultimately the performance of the extruder. For instance, a variable pitch screw can enhance material movement and reduce dead zones, which contributes to a more uniform melt and improved output quality. Additionally, the depth and angle of the screw flights can influence shear rates, affecting the thermal and mechanical properties of the extrudate.

Moreover, the choice of screw geometry must align with the specific requirements of the materials being processed. For example, high-viscosity materials may benefit from a longer compression zone, while the incorporation of mixing elements in the screw can help achieve better dispersion and homogeneity of additives or fillers. Understanding the relationship between screw design and material characteristics is essential for optimizing production efficiency. By carefully selecting screw geometry tailored to the application, manufacturers can achieve higher outputs and superior product quality, ultimately driving improved performance in their extrusion operations.

Maintenance Tips for Maximizing the Lifespan of Your Extruder Screw Barrel

When it comes to maintaining the longevity of your extruder screw barrel, implementing a regular maintenance schedule is crucial. First and foremost, ensuring that the barrel is kept clean from any residual materials will prevent contamination and reduce the risk of corrosion. Regularly inspect for any signs of wear or damage, as early detection can save you from costly repairs down the line.

Another essential tip is to monitor the temperature and pressure within the extruder. Consistent operating conditions help to minimize stress on the screw barrel, thereby extending its life. Make it a habit to review the manufacturer's guidelines for the best operating temperatures and pressures suited to the specific materials you are processing. This, coupled with routine lubricating of bearings and seals, will significantly enhance operational efficiency and durability.

Lastly, consider investing in high-quality feedback systems that notify you of potential issues before they escalate. This proactive approach will not only reduce downtime but also maintain consistent product quality. By following these maintenance tips, you can optimize the lifespan of your extruder screw barrel and improve overall production efficiency in your operations.