Global Excellence in Manufacturing: China’s Pride in Exporting Premium Extruder Screw Barrels

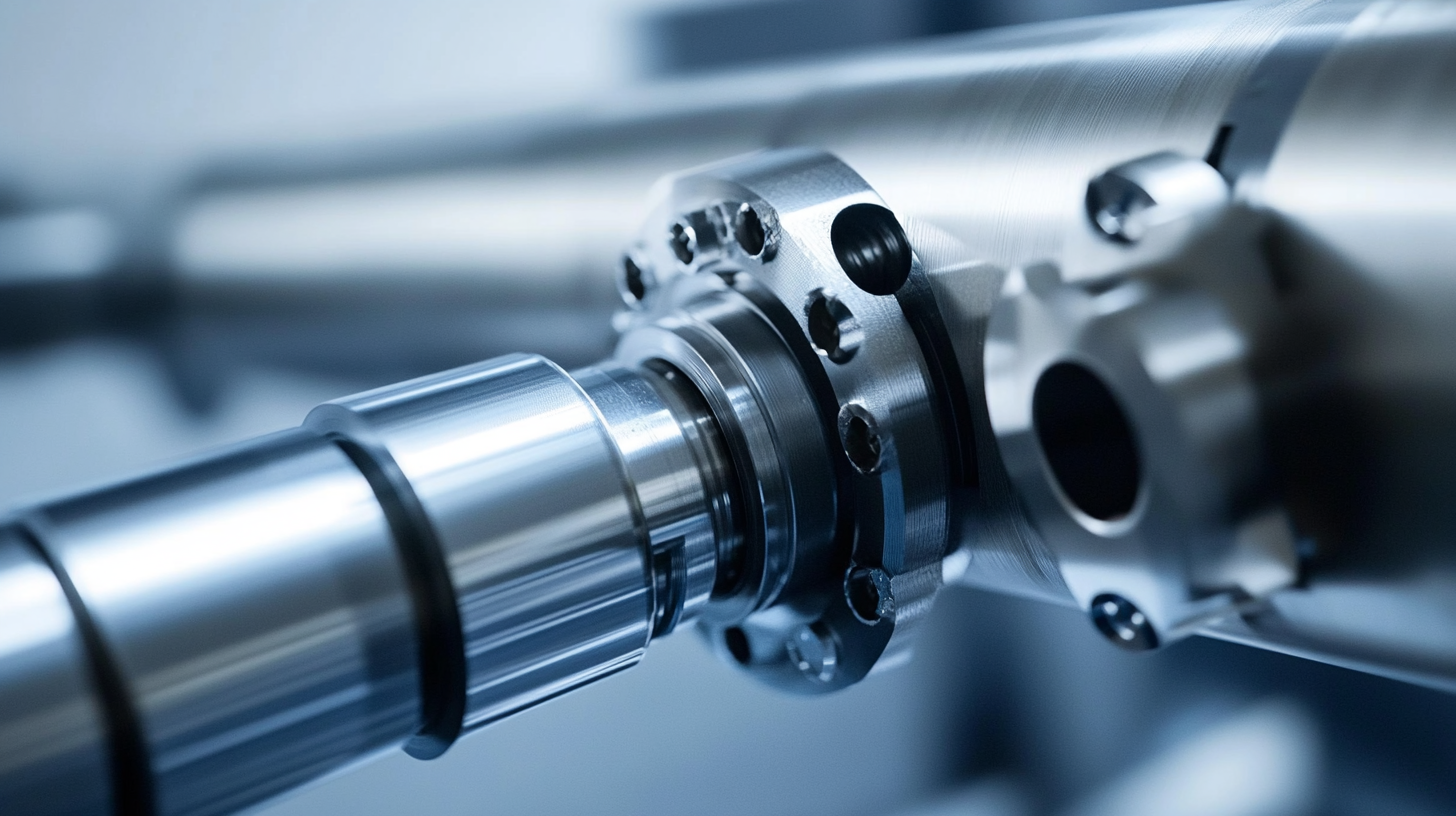

In the realm of global manufacturing, few components play as crucial a role in the production process as the extruder screw barrel. This vital piece of machinery is essential for transforming raw materials into high-quality products across various industries, particularly in plastics and rubber processing. China's dedication to engineering excellence has positioned it as a leader in the production and export of premium extruder screw barrels, showcasing remarkable innovations and advancements.

These advanced screw barrels not only enhance efficiency and durability but also reflect the nation's commitment to meeting international standards. As we delve into the intricacies of how China has achieved this level of quality and recognition, we will uncover the manufacturing techniques, technological innovations, and strategic practices that distinguish Chinese extruder screw barrels in the global market. Join us on this exploration of China's pride in engineering and its impact on the world of manufacturing.

Innovative Design Features of China's Premium Extruder Screw Barrels

China has emerged as a leader in manufacturing premium extruder screw barrels, recognizing the pivotal role these components play in various industries, including plastics and food processing. According to a recent market report by Research and Markets, the global extruder market is expected to reach $7 billion by 2025, with a significant portion attributed to advanced screw barrel technology. China’s innovative design features, such as enhanced corrosion resistance and improved thermal conductivity, have set new benchmarks for performance, contributing to increased efficiency and product quality.

One of the standout innovations in China’s extruder screw barrels is the incorporation of specialized alloys and surface treatments that extend service life and reduce maintenance costs. An analysis by Smithers Pira indicates that extruder screws produced with advanced materials experience less wear and tear, thereby enhancing production uptime. Furthermore, China's emphasis on precision engineering ensures that screw barrels provide consistent output and optimal mixing capabilities, which are critical in achieving superior product characteristics. As industries worldwide turn to Chinese manufacturers for these high-performance components, the emphasis on innovation continues to drive growth and competitiveness in the global market.

Key Technical Specifications for Optimal Performance in Manufacturing

In the competitive landscape of manufacturing, the technical specifications of extruder screw barrels play a vital role in enhancing production efficiency and product quality. Key parameters such as screw diameter, length-to-diameter (L/D) ratio, and pitch design significantly impact the performance of the extrusion process. According to a report by Smithers Pira, optimizing these specifications can lead to a 20% increase in throughput and a reduction in energy consumption by up to 15%. This remarkable efficiency highlights the importance of investing in high-quality extruder screw barrels, particularly those crafted in China, which has emerged as a global leader in this sector.

Furthermore, the materials used in the fabrication of extruder screw barrels are crucial for durability and performance. The choice of alloy, surface treatment, and heat treatment processes can determine the lifespan of the barrels and their resistance to wear. A study by the International Plastics Research Institute revealed that using advanced steel alloys with surface nitriding can extend barrel life by 30%, thereby minimizing downtime and enhancing productivity. As Chinese manufacturers continue to innovate and produce premium extruder screw barrels, their technical excellence is setting new benchmarks in the global manufacturing arena.

Global Excellence in Manufacturing: China’s Pride in Exporting Premium Extruder Screw Barrels

| Dimension | Specification | Material | Coating | Performance Parameter |

|---|---|---|---|---|

| Diameter | 20 mm to 250 mm | Alloy Steel | Nitrided | Up to 1000 RPM |

| Length | 500 mm to 4000 mm | Stainless Steel | Hard Chrome | High Wear Resistance |

| Screw Type | Conical/Straight | Tool Steel | PTFE Coated | Efficient Melting |

| Flight Height | 3 mm to 25 mm | HARDENED Steel | Ceramic Coated | Thermal Conductivity |

| Tolerance | ±0.05 mm | Bimetallic | No Coating | Corrosion Resistance |

Step-by-Step Guide to Selecting the Right Extruder Screw Barrel

When it comes to selecting the right extruder screw barrel, understanding your specific manufacturing requirements is crucial. Firstly, consider the material you will be processing. Different materials, such as thermoplastics or rubber, demand different screw designs and barrel configurations. Make sure to select a screw barrel that is optimized for the material characteristics to ensure smooth processing and quality output.

Tip: Always consult with manufacturers about the compatibility of the screw barrel with your intended materials. This can prevent costly adjustments later on.

Next, evaluate the required throughput and viscosity of the material. Higher viscosity materials may require a specially designed screw geometry to ensure efficient feeding and mixing. Additionally, consider the dimensions and length of the screw barrel as they can directly impact the processing time and the physical properties of the final product.

Tip: Conduct a thorough analysis of your production rates and material flow patterns. Matching these elements with the screw barrel specifications can significantly enhance production efficiency and reduce waste.

Quality Control and Testing Methods for Extruder Screw Barrels

In the realm of manufacturing, particularly in the production of extruder screw barrels, stringent quality control and testing methods are paramount. The complexity of extruder screw design necessitates a comprehensive quality assurance process to ensure that each component meets rigorous standards. Manufacturers in China have adopted advanced inspection techniques, including non-destructive testing and precision measuring tools, to analyze the performance and durability of screw barrels. These methods help identify any potential defects that could compromise the functionality of the barrels during extrusion processes.

Moreover, the testing phase plays a critical role in certifying the reliability of extruder screw barrels. Manufacturers typically conduct thermal and mechanical stress tests to evaluate how these components respond under pressure and varying temperatures. Data gathered from these tests allows engineers to optimize designs and enhance production processes, ensuring that the final product not only meets client specifications but also exceeds international quality benchmarks.

By embedding quality control at every stage of production, Chinese manufacturers proudly embody global excellence, positioning themselves as leaders in the export of premium extruder screw barrels.

Benefits of Choosing China's Extruder Screw Barrels for Global Markets

In the realm of global manufacturing, China's extruder screw barrels have emerged as a symbol of quality and precision, catering to diverse industries. The benefits of choosing Chinese manufacturers for these vital components are abundant, especially for businesses looking to enhance their production efficiency. Chinese extruder screw barrels are known for their high durability, corrosion resistance, and innovative designs, which significantly reduce downtime and maintenance costs. This competitive advantage makes them an ideal choice for companies aiming to optimize their production processes.

When selecting extruder screw barrels, consider the following tips to maximize your investment. First, ensure that the manufacturer employs advanced materials and state-of-the-art technology in production. This guarantees not only longevity but also consistent performance. Second, prioritize suppliers that offer customization options to tailor the barrels to your specific operational needs. A well-fitted extruder screw barrel can lead to improved output and reduced wear and tear.

Moreover, take advantage of China's robust supply chain and logistics capabilities. By collaborating with experienced manufacturers, you can benefit from timely deliveries and responsive customer service, ensuring that your production line runs smoothly. Embracing these advantages will position your business for success in the increasingly competitive global market.