Future Innovations in Best Extruder Screw Barrel Technology for 2025

As we look towards 2025, the evolution of extruder screw barrel technology is set to revolutionize the manufacturing landscape, offering unprecedented advancements that cater to the diverse needs of the plastics and polymers industries. This blog explores the future innovations in extruder screw barrel designs and their potential benefits, including enhanced efficiency, improved material processing, and significant cost savings. With the continuous push towards sustainability and higher production standards, understanding the upcoming trends in extruder screw barrel technology will be essential for manufacturers seeking to remain competitive. By delving into the anticipated developments in this critical component, we aim to provide insights that will help industry professionals make informed decisions, foster innovation, and ultimately drive their businesses forward in a rapidly changing technological environment.

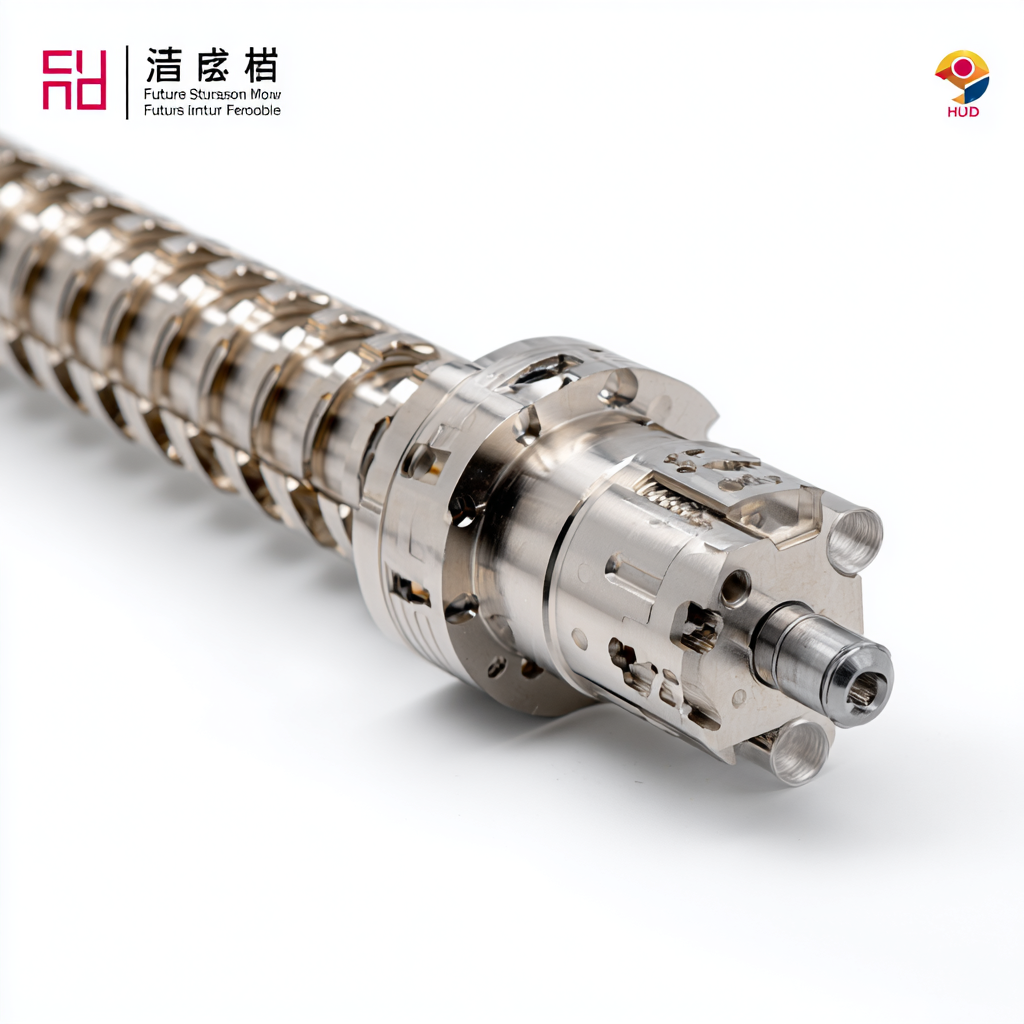

Emerging Trends in Extruder Screw Barrel Design for Enhanced Performance

The future of extruder screw barrel design is evolving rapidly as industries seek enhanced performance and efficiency. Emerging trends highlight the adoption of advanced materials and designs that cater to the increasing demand for versatility and customization. Innovations in twin-screw granulation (TSG) are particularly noteworthy, as this technology finds burgeoning applications in the pharmaceutical sector, manifesting its potential in developing unique formulations that meet stringent regulatory requirements. As manufacturers explore ways to optimize processing capabilities, the integration of intelligent control systems into extruder designs is becoming more prevalent, allowing for real-time adjustments and improved product quality.

Moreover, the extruded snacks market is witnessing a significant transformation driven by innovative technologies. Manufacturers are tapping into new ingredient trends that emphasize health and nutrition, leading to the development of products with higher protein content and functional benefits. This shift is pushing extruder equipment to adopt greater flexibility, enabling faster transitions between different formulations and minimizing downtime during production. The emphasis on eco-friendly materials, including starch-blended biodegradable polymers, is further fueling advancements in extrusion technology, as businesses strive to align with sustainability goals while catering to consumer preferences for environmentally conscious products.

Addressing Common Challenges in Extruder Technology: Material Limitations

As we look towards 2025, the extruder manufacturing industry is poised for significant advancements, particularly in addressing the common challenges related to material limitations. Data from the Plastic Industry Association indicates that approximately 30% of production downtime is attributed to material flow issues within extruder systems. This bottleneck not only hampers efficiency but also increases operational costs. Therefore, innovations in screw barrel technologies must focus on optimizing material handling and reducing the impact of these limitations.

Recent studies have emphasized the importance of materials with high thermal stability and improved wear resistance. Research by Smithers Pira highlights that advancements in polymer composites can enhance the longevity and performance of extruder screws and barrels, leading to better productivity rates. Additionally, the emergence of smart materials that can adapt to processing conditions presents an opportunity for the industry to minimize defects linked to inconsistent material behavior. As manufacturers embrace these breakthroughs, the capabilities of extruder systems will evolve, setting new standards for efficiency and reliability in 2025 and beyond.

Innovative Materials Shaping the Future of Extruder Screw Barrels

As we look ahead to 2025, the extruder screw barrel technology is set to undergo significant advancements primarily driven by the development of innovative materials. Recent industry reports indicate a growing demand for high-performance polymers and composite materials, which have been crucial in enhancing the durability and efficiency of extruder components. For instance, the global market for advanced extruder screw barrels is expected to reach USD 1.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.2%. This growth is largely attributed to manufacturers’ needs for better thermal stability and wear resistance, particularly in applications involving challenging materials like recycled plastics.

Moreover, the integration of new alloyed metals and reinforced plastics is likely to revolutionize the design of extruder screws and barrels. A study from the Polymer Processing Society highlights that adopting advanced materials could improve processing speeds by up to 30% while reducing energy consumption by 15%. These innovations not only enhance production line efficiency but also align with sustainability goals by promoting the recycling and use of eco-friendly materials. As we prepare for the next wave of technological breakthroughs, the shift toward these innovative material solutions will undoubtedly play a pivotal role in shaping the future of extruder screw barrels.

The Role of Automation and AI in Improving Extruder Efficiency

As we look forward to innovations in extruder screw barrel technology for 2025, the integration of automation and artificial intelligence (AI) becomes increasingly critical in enhancing extruder efficiency. Recent industry reports indicate that companies implementing AI-driven systems have reported efficiency gains of up to 20%, largely due to improved process optimization and predictive maintenance capabilities. By leveraging real-time data analytics, manufacturers can make informed decisions that reduce waste and energy consumption, which is vital for sustainability in production processes.

To maximize the benefits of automation and AI, here are a few tips: first, invest in robust data collection systems that monitor machine performance. This foundational step ensures that AI algorithms have access to accurate data to analyze and recommend optimizations. Second, consider gradually introducing AI tools into your operations, allowing your team to adapt while minimizing disruption. Finally, prioritize training for your staff on new technologies to ensure they can effectively leverage the advancements offered by AI.

By embracing these innovations, the extruder industry can not only increase productivity but also enhance the overall quality of produced materials, positioning themselves favorably in a competitive market. The future of extrusion is indeed intertwined with technology's rapid evolution.

Future Innovations in Best Extruder Screw Barrel Technology for 2025 - The Role of Automation and AI in Improving Extruder Efficiency

| Dimension | Description | Expected Impact by 2025 |

|---|---|---|

| Automation | Integration of automated controls to enhance precision in extrusion processes. | Improved consistency and reduced material waste. |

| AI Optimization | Using AI algorithms to predict and adjust processing parameters in real-time. | Enhanced efficiency and reduced downtime. |

| Smart Sensors | Deployment of smart sensors for monitoring machine performance and product quality. | Real-time data collection leading to informed decision-making. |

| Material Science Advancements | Development of new materials with improved thermal properties for extruders. | Higher processing temperatures and better material flow. |

| Energy Efficiency | Innovative designs aimed at reducing energy consumption in extruders. | Lower operational costs and reduced carbon footprint. |

Sustainability in Extruder Screw Barrel Manufacturing: Sustainable Practices to Watch

Sustainability is becoming a focal point in the manufacturing of extruder screw barrels, particularly as we approach 2025. Advanced process technologies are paving the way for significant energy efficiency and productivity improvements within both traditional and synthetic rubber plants. The integration of these technologies not only reduces operational costs but also minimizes environmental impact, aligning with the global push for greener industrial practices.

Tips for achieving sustainability in extruder screw barrel manufacturing include leveraging innovative materials and processes. For instance, utilizing bio-based polymers and exploring the extrusion of carbon fiber-reinforced polymers can enhance the sustainability profile of products. Additionally, adopting real-time monitoring systems for energy consumption can help pinpoint areas for efficiency gains, thereby reducing the overall carbon footprint of the production process.

Another emerging trend is the development of 3D printing filaments from sustainable sources, such as PHB-starch blends. This approach not only promotes the use of renewable materials but also addresses waste management by transforming biodegradable resources into valuable end products. Manufacturers should also consider exploring ways to incorporate waste materials into their processes, thus contributing to a circular economy and promoting sustainable practices in extruder screw barrel technology.