7 Tips to Choose the Best Rubber Screw Barrel for Your Manufacturing Needs

In the competitive landscape of manufacturing, selecting the right components is crucial for optimizing production efficiency and product quality. One of the pivotal elements in rubber processing is the rubber screw barrel, which plays a vital role in the extrusion and mixing processes. According to a recent report by Smithers, the global rubber processing machinery market is projected to reach USD 4 billion by 2025, highlighting the growing demand for effective and reliable equipment. The right rubber screw barrel can significantly impact material consistency and machine uptime, ultimately influencing production costs. Therefore, understanding the intricate details of rubber screw barrel selection is essential for manufacturers aiming to enhance their operational capabilities and meet industry standards. In this blog, we will explore seven essential tips to help you choose the best rubber screw barrel tailored to your specific manufacturing needs.

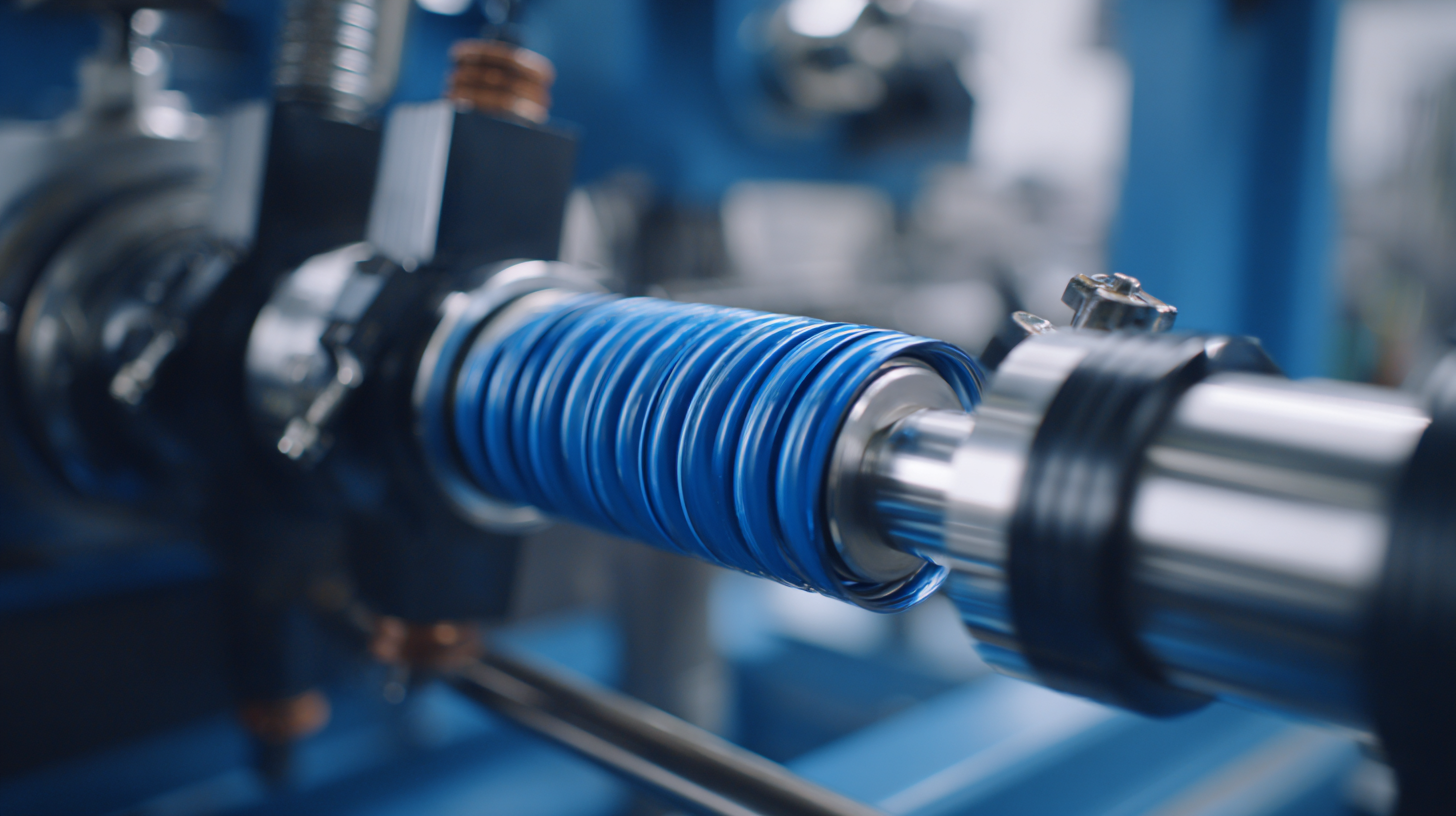

Understanding the Importance of Rubber Screw Barrels in Manufacturing

Rubber screw barrels play a crucial role in the manufacturing sector, significantly influencing the quality and efficiency of rubber processing. As outlined in a recent industry report by Smithers, the global market for rubber processing machinery is expected to reach USD 5.2 billion by 2025, highlighting the increasing importance of optimal machinery, including screw barrels. These components not only facilitate the mixing and conveying of raw rubber but also ensure consistent output in production lines. The choice of a rubber screw barrel can affect everything from material quality to production speed.

When selecting the best rubber screw barrel for your needs, consider the following tips: First, assess the compatibility of the barrel material with your specific rubber formulations. This can enhance wear resistance and prolong the life of the equipment. Second, evaluate the barrel’s design, as features like grooved or reverse-pitch designs can significantly impact mixing efficiency and melt homogeneity, which are vital in producing high-quality rubber products. Lastly, consult with manufacturers about the potential for customization to better suit your production requirements, as tailored solutions can lead to marked improvements in productivity metrics.

By prioritizing the right rubber screw barrel, manufacturers can ensure that their operations run smoothly, maintaining the quality and efficiency needed to compete in an ever-evolving market.

Key Factors to Consider When Selecting Rubber Screw Barrels

When selecting a rubber screw barrel for manufacturing, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, the material of the screw barrel plays a vital role in its longevity and ability to withstand wear and tear. High-quality materials, such as nitrided steel or bimetallic coatings, can enhance durability and improve resistance to corrosion, which is essential for maintaining the integrity of the production process.

Another critical aspect is the design of the screw barrel. The geometry, including the screw diameter, length, and flight design, significantly impacts the processing of rubber materials. Manufacturers should assess their specific processing requirements and choose a design that facilitates proper material flow and mixing. Additionally, the compatibility of the barrel with the rubber compounds being processed is crucial, as different materials may require unique thermal and mechanical properties. Understanding these factors will lead to informed decisions that enhance productivity and reduce downtime.

Different Types of Rubber Screw Barrels and Their Applications

When selecting the best rubber screw barrel for your manufacturing needs, understanding the different types and their applications is essential. Rubber screw barrels come in various configurations, including single screw, twin screw, and intermeshing screws, each designed for specific processing tasks. Single screw barrels are commonly used for basic extrusion processes, making them suitable for applications where consistent melt flow is crucial. In contrast, twin screw barrels provide enhanced mixing capabilities, ideal for blending various materials or additives into the rubber matrix.

Each type of screw barrel presents unique advantages and challenges. For instance, while single screw barrels are generally easier to maintain, they might not handle highly flexible materials efficiently. This is particularly important in elastomer processing, where issues such as filament buckling can arise. The flexibility of certain elastomers can lead to difficulties during extrusion, especially when feeding through rollers or liquefier heads. Understanding these properties will not only help in selecting a suitable design but also ensure optimal performance in rubber processing and manufacturing applications.

Maintenance Tips to Extend the Life of Your Rubber Screw Barrel

When it comes to maintaining your rubber screw barrel, implementing proper care routines is essential for extending its lifespan. Regular cleaning is one of the foundational tips; residue build-up can affect performance and lead to premature wear. After each production cycle, ensure that all leftover materials are thoroughly removed. Using the appropriate cleaning agents specific to rubber materials can also help maintain the integrity of the barrel surfaces.

Another vital aspect of maintenance involves regular inspections. Routinely check for signs of wear or damage, such as cracks or uneven surfaces. Early detection of these issues allows for timely repairs, preventing costly breakdowns. Furthermore, lubricating the screw barrel components based on manufacturer recommendations can significantly enhance its operational efficiency and longevity.

Lastly, make sure to follow the manufacturer's guidelines on temperature and pressure settings during operations. Operating outside of these parameters can accelerate wear and lead to failures. By adhering to these maintenance tips, you can ensure your rubber screw barrel remains in optimal condition, driving productivity and efficiency in your manufacturing process.

Evaluating Supplier Credibility for Quality Rubber Screw Barrels

When selecting a supplier for rubber screw barrels, evaluating their credibility is paramount to ensure the quality and reliability of your manufacturing processes. A credible supplier will have a proven track record of delivering high-quality products consistently. Start by researching the supplier's reputation within the industry. Look for customer reviews, testimonials, and case studies that highlight their experience with rubber screw barrels. Engaging with existing customers can offer valuable insights into the supplier's product quality and customer service capabilities.

Additionally, it is crucial to assess the supplier's certifications and compliance with industry standards. A reputable supplier should have relevant certifications, indicating their commitment to maintaining quality control throughout the manufacturing process. Certifications such as ISO 9001 demonstrate that the supplier adheres to internationally recognized quality management standards. Beyond certifications, consider the supplier's willingness to provide detailed product specifications and data sheets. This openness reflects their transparency and dedication to ensuring that you make informed purchasing decisions based on quality and performance.